In-depth exploration of fault logging: A new tool for equipment maintenance

Release time:

2025-07-17

Understand the principles and applications of fault logging to improve equipment maintenance efficiency and ensure production safety.

What is fault recording?

Fault recording, as the name suggests, is the process of recording the occurrence and related data of equipment malfunctions. This technology is increasingly valued in modern industry, especially in the fields of electricity and machinery. Through fault recording, we can better understand the causes of faults and thus develop effective maintenance plans.

Working principle of fault recording

The core of fault recording lies in data acquisition and storage. During operation, the equipment continuously monitors its electrical parameters, temperature, pressure, and other information. When the system detects an abnormality, the fault recorder immediately starts and records various data before and after the fault occurs. This data includes not only the instantaneous state when the fault occurs, but may also involve the trend changes before the fault.

Why is fault recording so important?

First, fault recording helps us quickly locate problems and avoid lengthy troubleshooting processes. Imagine if equipment malfunctions at a critical moment, delaying production progress, it would be counterproductive! Secondly, data analysis from fault recording can provide valuable references for future equipment maintenance, preventing similar problems from happening again. In short, fault recording is like a "diagnostic doctor" for equipment, providing us with practical information.

Practical application cases of fault recording

In a large power company, they widely use fault recording technology in substations. Once, an important piece of equipment in a substation malfunctioned suddenly. Through the fault recording, engineers quickly analyzed the cause of the fault and found that it was caused by overload. Therefore, they adjusted the equipment load in time, avoiding a larger-scale power outage. This successful case fully verifies the effectiveness of fault recording.

How to choose suitable fault recording equipment?

When choosing fault recording equipment, we can consider the following aspects: First, the sampling frequency of the equipment should be high to ensure that rapidly changing signals can be captured; second, the storage capacity should be large to store long-term data; finally, the ease of use of the equipment is also important, and easy operation can save a lot of time. In short, choosing the right fault recording equipment is like choosing the right tools, which can make us twice the result with half the effort.

Fault recording, as a powerful tool for modern industrial equipment maintenance, has been increasingly recognized by the industry. By monitoring and analyzing faults in real time, we can not only solve problems in time, but also provide a reliable basis for future production. Whether it is a large enterprise or a small factory, the application of fault recording technology can improve the safety and stability of equipment, which is a technology worth investing in!

Keyword:

Recent information

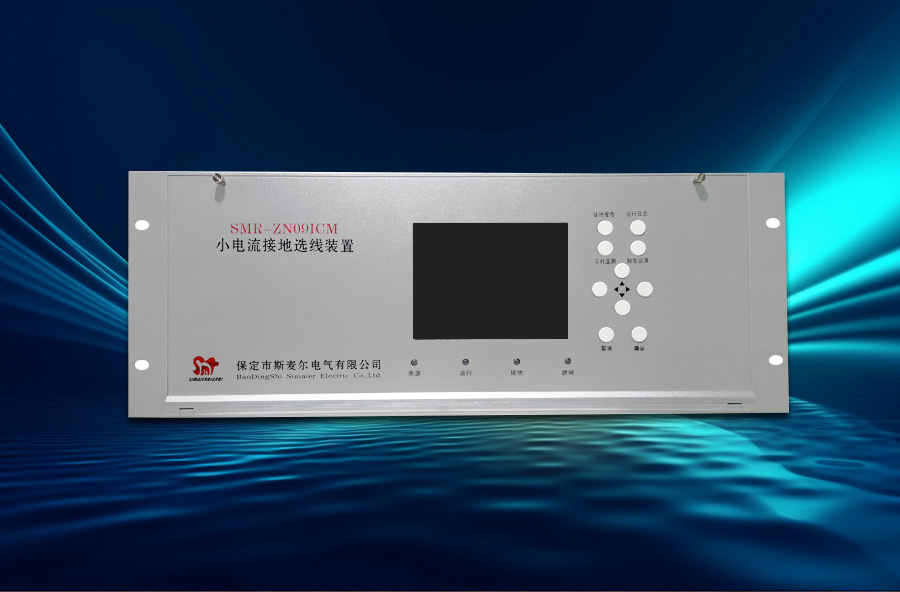

The main factors of insufficient selection principle for small current grounding.