The Working Principle and Importance of Power Quality Monitoring

Release time:

2025-11-17

Delve into the working principles of power quality monitoring and its importance in modern power systems.

In today’s electrically driven era, monitoring power quality has become particularly important. Have you ever wondered how power quality affects the various electrical appliances we use in our daily lives? From household refrigerators to industrial production lines, power quality directly impacts the efficiency of these devices.

Simply put, power quality monitoring uses technological means to detect in real time parameters such as voltage, current, and frequency in the power system, ensuring the stability of the power supply. Imagine this: if the voltage is too high or too low, your household appliances could get damaged—something none of us would want to see. That’s why power quality monitoring is like a “health check” for the power system, making sure everything is running smoothly.

Power quality monitoring relies primarily on a series of sensors and monitoring devices. These devices collect various types of data from the power system, analyze and process the data, and ultimately generate visualized reports. Specifically, they monitor the following aspects:

- Voltage fluctuation: The instantaneous change in voltage may affect the normal operation of the equipment.

- Frequency offset: Frequency stability is crucial for the safety of power systems.

- Harmonic Analysis: Harmonics can cause issues such as equipment heating and power loss.

- Transient event: Such as sudden conditions like lightning strikes or short circuits.

Through these monitoring efforts, the power company can promptly identify problems, take corrective measures, and prevent greater losses.

The application of power quality monitoring extends beyond just power companies. In fact, many large industrial enterprises, commercial buildings, and smart home systems are actively adopting this technology. For example, certain manufacturing companies use power quality monitoring systems to optimize their production processes, reduce energy consumption, and enhance productivity. By monitoring data in real time, they can respond more quickly to potential power issues, ensuring the continuous operation of their production lines.

Keyword:

Recent information

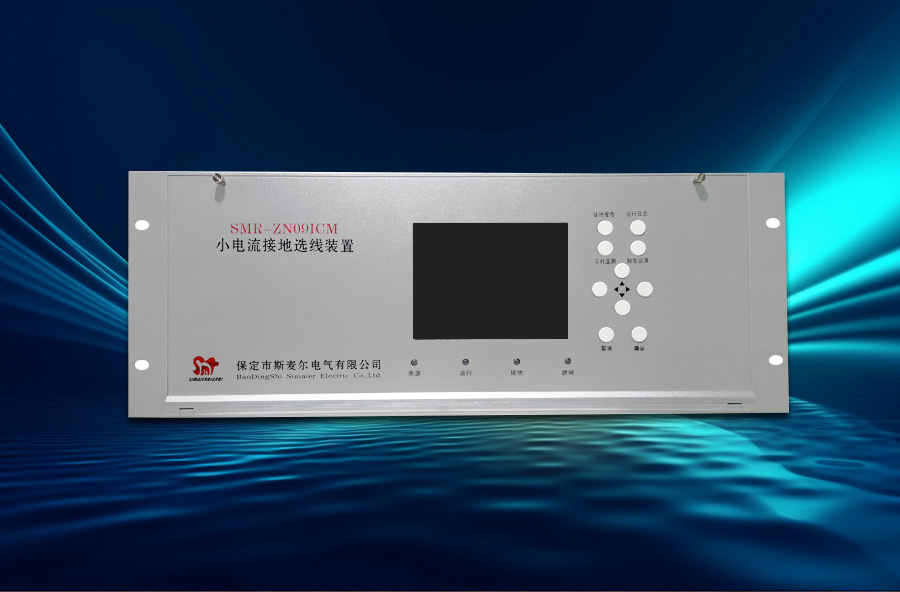

The main factors of insufficient selection principle for small current grounding.